Enzymatic Workhorses, State-making Practices, and Sustainable Denim Dye

From the Series: Substitution

From the Series: Substitution

Blue jeans are iconic, loved for their durable quality and distinct appearance. However, the denim dyeing industry ranks among the most polluting textile industries globally. At a research center in Denmark, scientists are working to develop chemoenzymatic indican, a substitute for the petrochemicals used in the denim dyeing industry. The identification of an enzyme from the plant indigo polygonum tinctorium, commonly referred to as Japanese indigo, is the first step.

Yet, what kind of substitution is implied by chemoenzymatic indican? Moreover, how does the turn to enzymes to further a sustainable denim dyeing industry inform Denmark’s shifting state-making practices? This turn to the microscale to effect societal and environmental transformation is set in motion by problems that follow from the use of older materials. At issue is how Denmark, along with other nations in the Global North, perpetuate their image as states invested in delivering technological solutions while continuing to export the production and dyeing industry to countries located at the other end of the commodity chain. Thus, substitution refers to displacement of value in which a specific configuration and continuation of the geopolitical axes between the Global North and South are at stake.

Denmark is among the international leaders in fashion design and home to several companies that contribute substantially to fast fashion. Politically, the Danish fashion industry is of specific interest due to its economic growth potential. By seeking to further a sustainable denim dyeing industry, the science on chemoenzymatic indican finds a perfect fit with the ambitions of the Danish state in remaking itself as an emerging leader in the bioeconomy. Yet, the scientific interest in harnessing the catalytic forces of enzymes to prove that fashion can be sustainable does not entirely obviate the process of petro-extractivism.

Though the vision of the research center includes replacing fossil fuels with enzymes and cells, the substitution involved in producing indican will not be entirely “bio” at this stage. The process begins with the use of petrochemicals such as aniline, derived from benzene and formaldehyde, derived from natural gas. This part of the process mimics the initial step of establishing synthetic indigo dye, which takes us to the importance of materiality for transforming society, science, and industry (Pickering 2005). In determining the chemical structure of indigo and combining it with waste products derived from coal tar, the chemical dyeing industry was born and along with it, new consumption patterns. Yet, while fossil fuels enabled the rise of the dyeing industry, it is its unanticipated effect on the environment that is the target of present science: scientists are working to harness the capabilities of an enzyme to replace the harsh chemicals added at the dyeing stage.

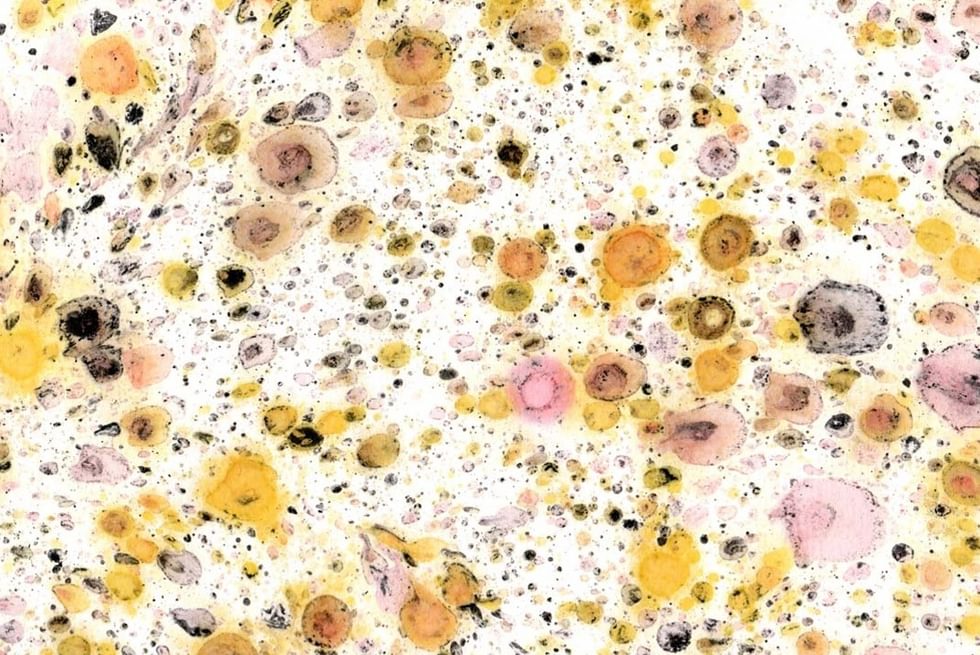

This leads us to question how the science to enable chemoenzymatic dye aligns with and differs from earlier modes of producing indigo dye. Indigo is produced naturally as a part of the plant’s biochemical defense in response to the surrounding environment, such as insects. When a leaf is damaged, the vacuole holding indican (a precursor) bursts and an enzymatic reaction is set in motion, releasing another chemical, indoxyl, giving rise to the distinct blue dye indigo. Although present science appears to repeat the initial step in the natural production of indigo dye, the methods and site of the work are different. The initial step involves identifying the specific enzyme (PtUGT1) involved in the biochemical defenses of Japanese indigo and solving the structure of the enzyme essential to determining its function (Myers 2015). Subsequently, scientists modify the structure of the enzyme through engineering an optimized sequence for application at industrial scale.

When enzymes become imbued with the potential to enable a shift from chemistry to biology in industry, the substitution is embedded in the development of recombinant DNA technology and AI. What is important about this form of substitution—from chemical to biological—is its role as a “plug-in technology” for application at existing dyeing mills, obviating the need for new infrastructure or training of personnel (Ulrich 2023).

While so far, we have been concerned with the techniques and enzymatic forms involved in substitution at the micro scale, what if we considered substitution through the shifting state-making practices in Denmark? The hybrid assemblage of chemo-enzymatic dye continues on the macro-scale, accompanied by a cycle of displacement in the textile commodity chain.

The science of the sustainable production of a chemoenzymatic substitution aligns with Denmark’s political and economic interests in becoming a leader in this emerging bioeconomy founded upon generating surplus value, while simultaneously being a better, environmentally benign, and ethically responsible alternative (Asdal et al. 2021). Of interest is Denmark’s role in furthering sustainable fashion through development of technologies though Danish environmental regulations and salaries prevent the operation of conventional denim dyeing mills on Danish soil. As a result, the work is outsourced to Turkey or countries in Southeast Asia with fewer environmental regulations. While the Danish state is focused on combining economic growth from fashion with the life sciences—another politically and economically important sector in Denmark—the engagement reflects a particular distribution of labor. In this state-making practice the technology to further the sustainability of denim dyeing depends on the production of fabrics, dyeing, and sewing occurring outside of Europe, which reflects the dispersed value chain.

At the other end of the chain, are the Danish consumers who purchase three times as much clothing as the global average consumer. Political concerns have been raised regarding the “over consumption” of fast fashion, leading politicians to urge the European Union to legislate the field. An issue in Danish policy is the excess generated from this consumption, as most textiles end up in incinerators. The National Bioeconomy Panel insists that the Danish state should be a frontrunner in developing a system for collecting used textiles and for reusing this waste to mitigate another problem (Shell 2020): much of the clothing donated to European charities ends up in landfills or on the shores of Ghana even though these so-called “dead white man’s clothes” were intended for sale on local markets.

The aim of this essay has been to show how the present turn to microorganisms in science and the collection of textiles follows in the wake of past scientific engagements with older materials that continue to accumulate in the present. What has followed from the emergence of synthetic dyes was a globally dispersed commodity chain, which is still at work in current substitution that includes labs of the Global North providing technologies to improve the sustainability of denim dye while continuing to export the waste of the dyeing industry to countries located at the other end of the commodity chain. Thus, substitution actually refers to displacement of value, contributing to problems on a global scale whereby some nations are harvesting the bioeconomy’s “gold” while others are flooded in residues of past economies.

Asdal, Kristin, Béatrice Cointe, Bård Hobæk, Hilde Reinertsen, Tone Huse, Silje R. Morsman, and Tommas Måløy. 2021. “‘The Good Economy’: A Conceptual and Empirical Move for Investigating How Economies and Versions of the Good are Entangled.” BioSocieties 18: 1–24.

Myers, Natasha. 2015. Rendering Life Molecular: Models, Modelers, and Excitable Matter. Durham, N.C.: Duke University Press.

Pickering, Andrew. 2005. “Decentering Sociology: Synthetic Dyes and Social Theory.” Perspectives on Science 13, no. 3: 352–405.

Ulrich, Katie. 2023. “The Substitute and the Excuse: Growing Sustainability, Growing Sugarcane in Sao Paulo, Brazil.” Cultural Anthropology 38, no. 4: 439–466.