Standard Substitution and the Politics of Cementing Equivalence

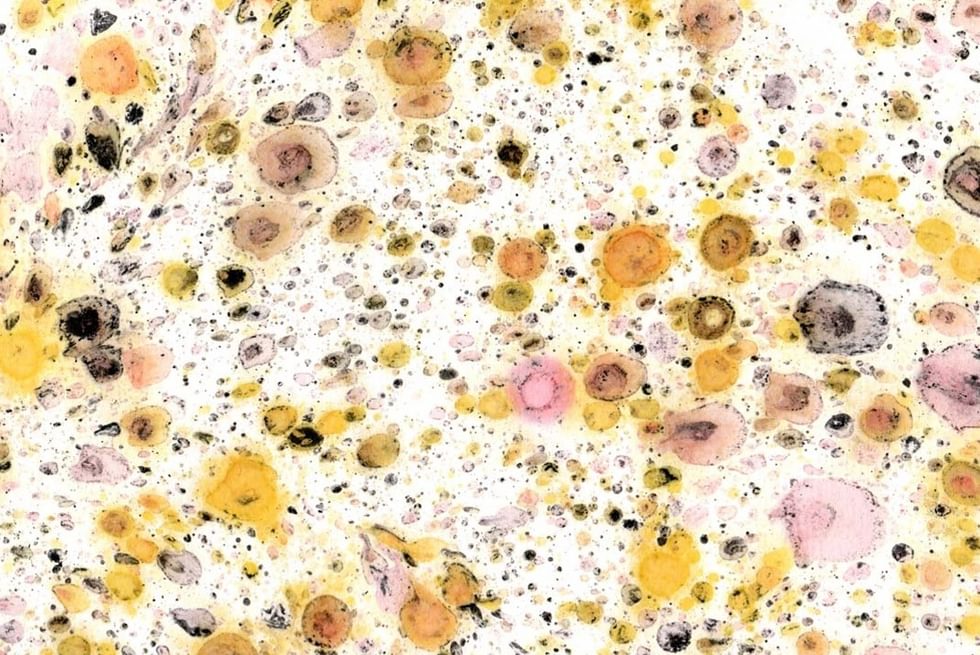

From the Series: Substitution

From the Series: Substitution

Concrete, which is made of cement, sand, stones, and water, is one of the most widely consumed materials on the planet, second only to water. Its insatiable consumption leads to the extraction of breath-taking volumes of geologically finite resources and the release of carbon dioxide (CO2) through the chemical decomposition of limestone as cement’s primary constituent. If the cement industry were a country, it would be the third-largest emitter of CO2, after the United States and China. Searching for alternative construction materials features centrally in debates about climate change and the Anthropocene.

The assumption that a new product is superior to what it substitutes for is linked to product standardization and the creation of equivalences and differences. Discussing cement standardization provides interesting insights into the technopolitics of substitution. Although the problem of CO2 emissions is vital, I am concerned with an even more basic aspect of cement, often taken for granted in long-industrialized, highly regulated societies: the standardization of a material with regard to its ability to ensure structural integrity and safety.

In other words, it is about preventing building collapse. This preoccupation is addressed through cement standards that define the composition of the cement mixture to meet a specific concrete strength. To regulate product equivalence and difference based on such performance involves an astounding amount of technical artifice. However, as one industry specialist with whom I spoke during my fieldwork in Nigeria questioned, what happens when the technical basis upon which the standard is predicated is founded on “an irrational technical argument?”

This essay focuses on the revision of Nigeria’s national cement standard. In August of 2014, the Standards Organisation of Nigeria (SON)—governed by the Federal Ministry of Industry, Trade and Investment—officially replaced the national cement standard to avoid becoming a “pariah state” on the issue of cement quality and building safety. 42.5 grade would substitute for 32.5 grade as the new cement standard for general purpose applications including casting of columns, beams, slabs, and moulding blocks, while 32.5 grade would be restricted to plastering work.

The revision has been more than a neutral technoscientific process resulting in a better regulatory outcome. Rather, political and economic twists and turns shaped the technical definition of product equivalence and difference. The story of the new Nigerian cement standard highlights that substitution is always political.

Technically speaking, a cement grade does not guarantee concrete strength. Concrete strength varies depending on many factors such as curing conditions, relative density, or degree of compaction. Grades are, instead, an indicator of the variable compressive strength in newton per millimetre squared (N/mm2) that cement yields in a standard test using a standard mix under standard conditions.

In other words, a grade refers to the measurement against which cement quality is tested to be standardized. 32.5 grade produces a compressive concrete strength anywhere between 32.5–52.5 N/mm2, 42.5 produces a compressive strength anywhere between 42.5N/mm2–62.5 N/mm2, and so on. 32.5 grade can therefore technically serve the same purpose as 42.5 grade. Achieving high concrete strength with a lower grade cement only requires higher ratios of cement in the mixture which increases the cost. Given that 32.5 and 42.5 grade could reach similar strengths, SON’s argument was technically ambivalent.

Various professional bodies, cement manufacturers, and other stakeholders signalled the impropriety of the regulator’s substitution decision. Three months before the decision was announced, Dangote Cement—the Nigerian cement company founded by Africa’s richest man, Aliko Dangote— instigated a public campaign against 32.5 grade cement. Some industry specialists I interviewed described it as a brazen move to mobilize support against 32.5 grade cement under the guise of a non-existent coalition of civil society groups called the Coalition Against Building Collapse. The coalition’s claim that only 42.5 grade cement guaranteed the concrete strength necessary for building safety was framed within a spate of building collapses that happened over the preceding decade and resulted in 226 fatalities across Nigeria. The regulatory discussions leading up to the new standard largely elided other factors such as widespread poor building practices and the incorrect application of specific grades for specific uses.

Situating the dispute within the global oil price collapse in 2014 explains in part why and how substitution was exploited to create value in a plummeting market context. The oil price fall proved disastrous for the Nigerian economic landscape. Dangote Industries Limited, the conglomeration of basic commodity businesses including sugar, salt, and rice, had to keep buoyant during the crisis amid escalating commodity prices and cut budgets. As industry specialists explained to me, despite a drastic reduction in global and local cement sales, Dangote Industries sought to leverage its flagship commodity through the production of higher-grade material to regain financial liquidity. Without demand, however, the product substitution would command little value.

The revision of the standard was a strategic attempt to dislodge the country’s then largest cement producer, Lafarge Africa Plc—a subsidiary of the French-founded, Swiss-acquired multinational giant. Although Lafarge had the technological capability to produce the higher grade, 80 percent of its facilities had been calibrated to produce 32.5 grade. Dangote Cement guaranteed itself a head start as the exclusive producer of the higher grade by equipping its facilities before its competitor even had any inkling about the new standard.

Dangote’s morally righteous argument—a higher cement grade to save lives by preventing building collapse—conceals the political manoeuvres that underpin the definition of equivalence and difference as a means to secure market power. And yet, the updated standard could even do more essential work by substituting the losses suffered by Dangote Industries’ other basic commodities businesses with Dangote Cement’s gains. Perhaps most significant is the ironic postcolonial twist of the manufacturer’s successful lobbying: standard substitution unseated decades of European domination in the Nigerian cement industry, setting the stage for the unprecedented rise of a homegrown African producer to become the largest cement multinational on the continent today.

The story unsettles the assumption that the replacement of one material by another is necessarily superior on a technical basis. In other parts of the world where attempts to decarbonize the industry have taken center stage, the ongoing revisions of cement and construction standards are no less likely the object of murky politics. As a mechanism of substitution, standards are a promising entry point to tease out the unavoidable presence of the political in seemingly technical decisions.